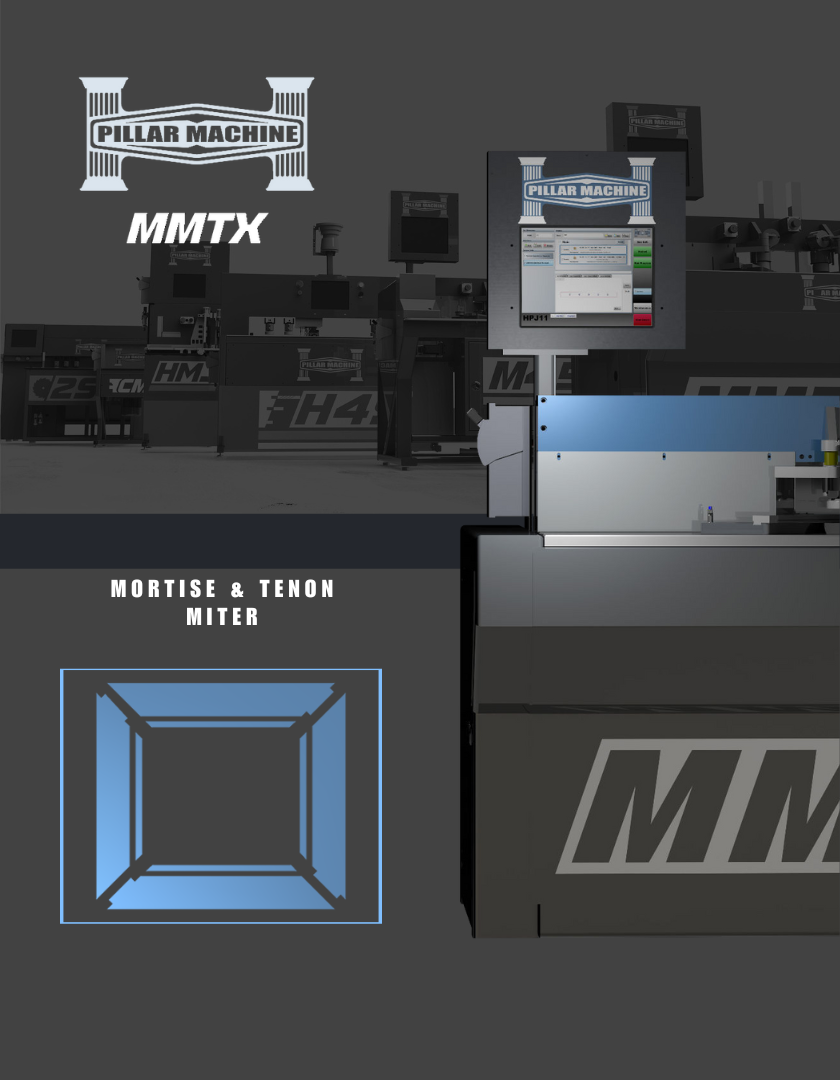

Pillar 6-Axis Miter, Mortise, Tenon Machine Center

Pillar 6-Axis Miter, Mortise, Tenon Machine Center

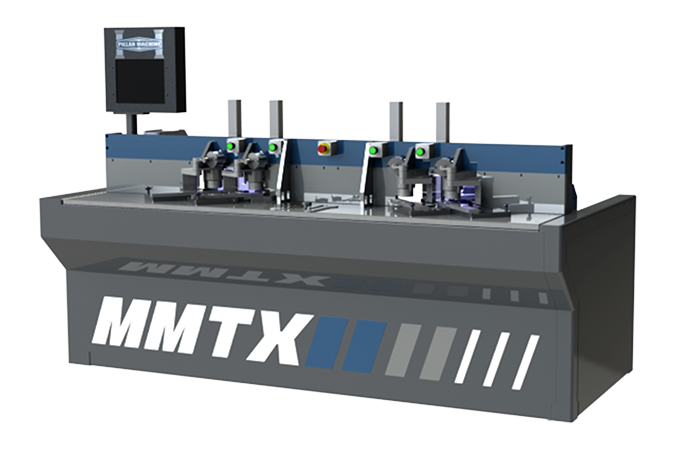

The MMTX is a dual carriage, 6 axis CNC controlled Miter Mortise and Tenon Machining Center – tailored specifically to meet high-volume production requirements.

MMTX Machine Description

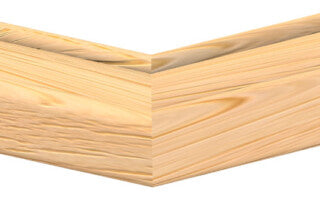

Offering flexibility as well as productivity, the MMTX provides high quality mitered mortise and tenon parts for use in cabinet door construction. This machine produces between 400-500 doors per 8 hour shift with one operator.

The MMTX is built on award winning technology. It won the “Challengers Award” at the 2004 IWF fair in Atlanta, Georgia.

Standard Operation

There are six CNC controlled axis between two machining carriages, each carriage contains one X axis (left to right), one Z axis (up and down), and one Y axis (in and out).

Parts are placed into the work zones, referencing the back and side fences. The start button is pressed, and the clamps secure the part into place. The machining is ready to begin in the work zone. There are 2 zones standard in the MMTX allowing for pendulum processing. While the one part is being machined, the other zone can be loaded and queued for machining.

Share